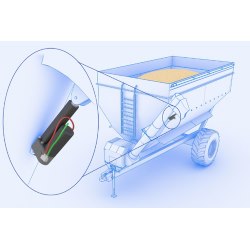

Spout Pivot

Remote Control on equipment functions, such as an extended auger spout, allow the operator to remain in the cab and will increase productivity and throughput. Positioning the spout accurately and reliably with Thomson electric actuators, remotely, allows operators to do it on the “fly” and dispense to trailing vehicles while harvesting - decreasing unproductive down time.

Key Benefits

Reduced Design Costs

- Single-switch operation and easy interface with multiple electronic controls.

- Eliminates the need to accommodate the large bend radius of hoses and to design a complicated system of hoses, valves, controls, filters and switches.

Reduced Installation Costs

- Fewer parts to install.

- Easy interface with multiple electronic controls and easy retrofit into existing applications.

Reduced Operating Costs

- Replaces costly, complicated hydraulic systems and long runs of hydraulic hoses.

- No hoses to fatigue and rupture, no filters to change, and no chance of debris entering the actuator operating system.

- Maintenance-free, lubricated for life and damage-resistant due to simple wiring connection.

Increased Safety and Productivity

- Allows the operator to quickly change implements from his seat; no extra operator required.

- Allows the operator to accurately and quickly position the spout from a distance

LT

LT  RU

RU  EN

EN