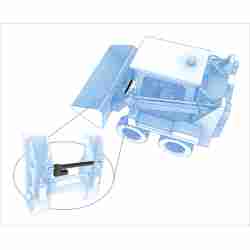

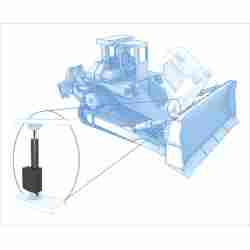

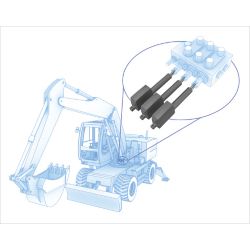

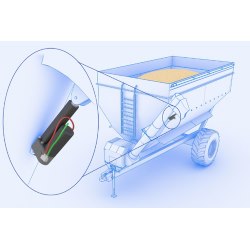

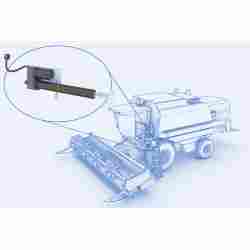

Throttle Control

The throttle is the key linkage between man and mobile off-highway machine, and Thomson electric linear actuators give operators an unprecedented range of control, for greater productivity, safety and sustainability.

Key Benefits

Reduced Design Costs

- Flexible potentiometer models allow easy interfacing, and multiple speed and feedback options add design flexibility.

- Compatible with multiple engine platforms as an add-on, and optional mounting brackets reduce design time

Reduced Installation Costs

- Optional mounting brackets and a variety of mounting accessories make installation easy.

- Actuator can be placed for easy installation; no direct access needed for maintenance, and there's no need to accommodate the large bend radius of wire-wound throttle cables.

Reduced Operating Costs

- Automatically allows return to low speed and rapid resumption of operating speed for economy and lower emissions.

- High cycle life, maintenance-free lifetime lubrication and high tolerance of heat, vibration and moisture.

Increased Safety and Productivity

- Automatic speed adjustments, lower fuel consumption and greater noise management reduce downtime and operator fatigue.

- Actuators allow much more ergonomic location of controls for less operator fatigue and more agile operation.

LT

LT  RU

RU  EN

EN